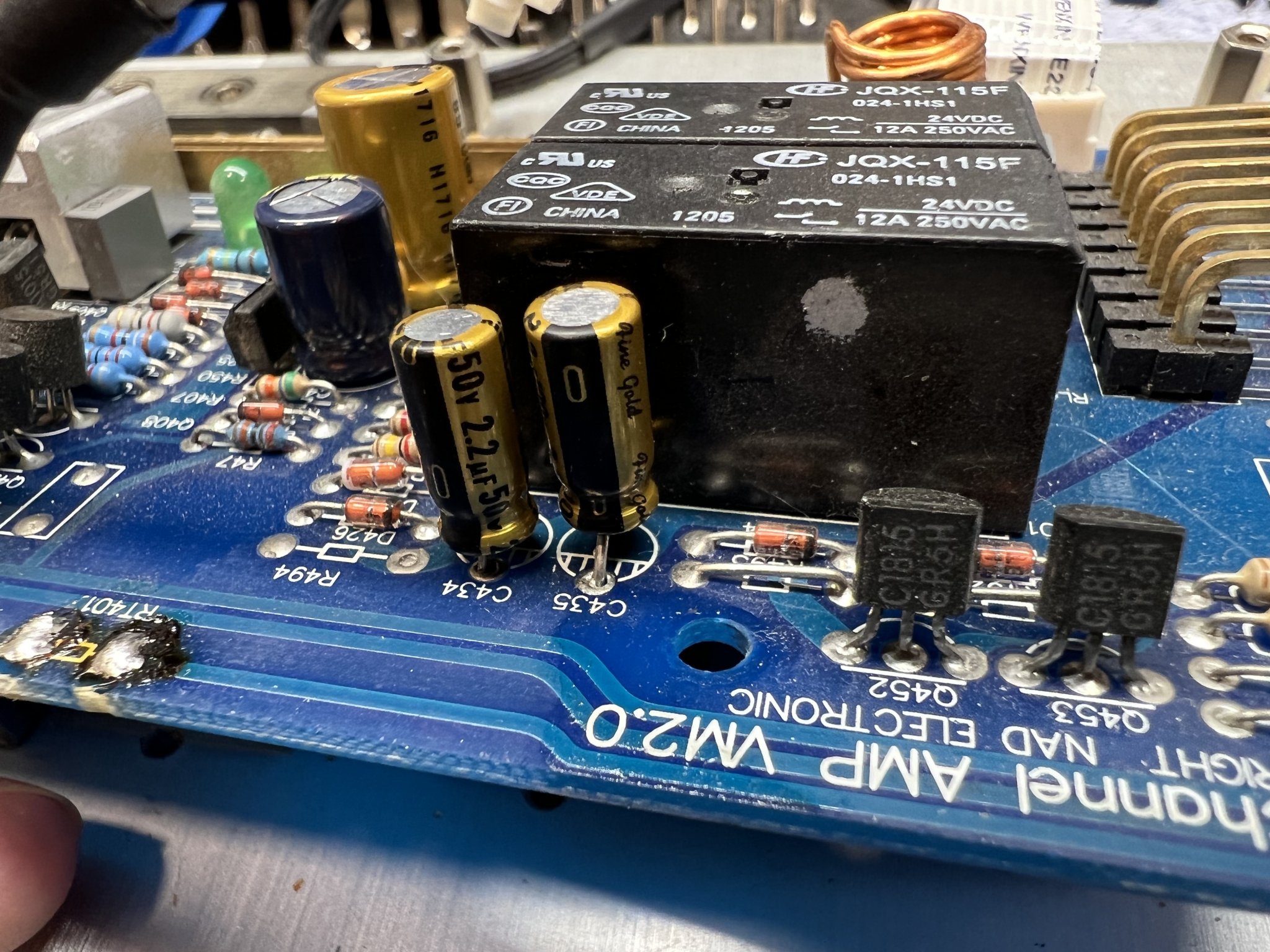

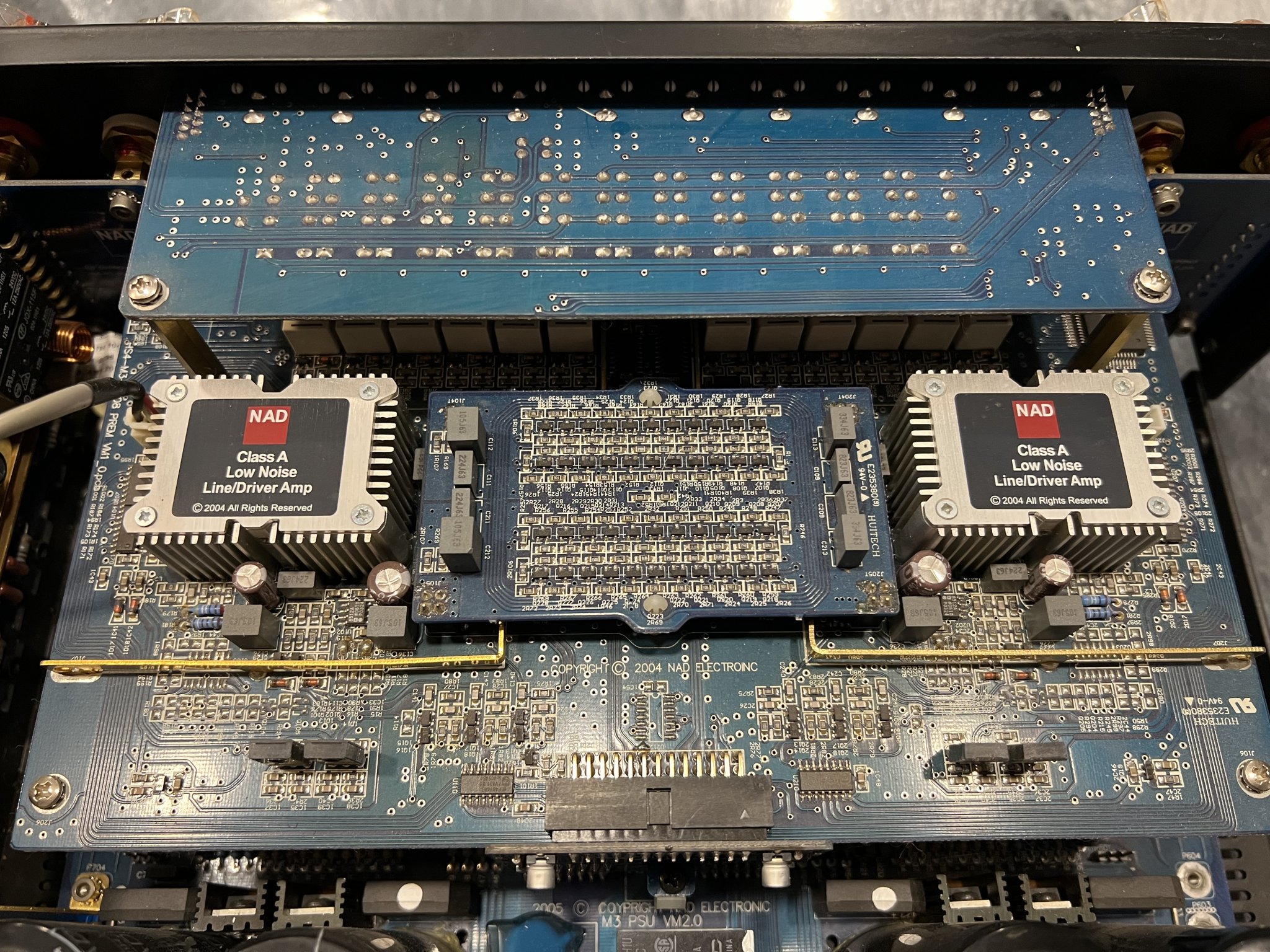

I received an NAD M3 in a small pile of broken gear. It is in mint condition otherwise, it powers up, but won’t come out if it’s protection mode. It isn’t very old, but seeing the four main filters all bulging I had an idea of what was wrong.

I disassembled it and am currently working on the two amplifier boards. Nearly every capacitor on the board has very high ESR, like a 330uF 16v with and ESR of 27 ohms. Not sure why they choose to use garbage caps, but I find more bad caps in NAD gear than anything else lol. Other than that it seems to be a really, really nice dual mono design.

I was thinking that while I had it apart that maybe I should do some modifications to it, see if I might be able to get some audible improvement.

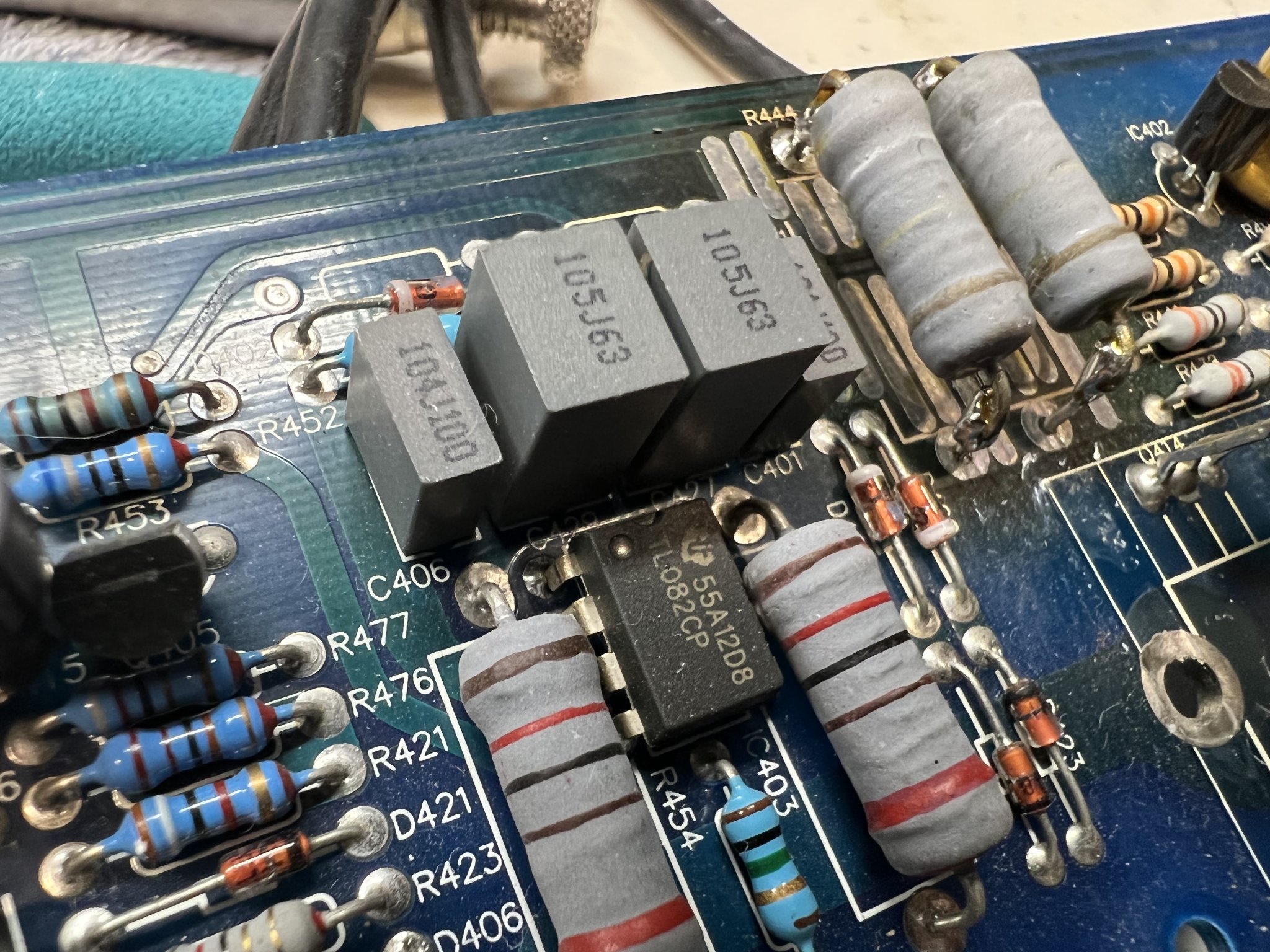

First: transistors, it uses decent signal transistors throughout the board, mostly being 2SC2240, 2SA970 and 2SC1815, 2SA1015. It also has a pair of 2SA1360 and a pair of 2SC3423. For drivers it uses 2SC4793 and 2SA1837, which I’ve read are actually pretty decent and make good drivers for the outputs I’m thinking of swapping to.

So it originally came with 4 2SC5200 and 4 2SA1943 in each channel. When asking about a transistor sub I learned that while this pair is okay (would have been a downgrade from what I wanted to sub), that a far superior pair would be the MJL3281 and MJL1302. I have several of each from Onsemi/Fairchild. Would this be a worthwhile improvement? Would there be an audible change noticed? Or would I just be wasting money and parts?

Next would be the opamp on each board. Currently uses TL082CP and thinking of an upgrade to maybe a an OPA device like 2134, maybe a 5532, maybe if I’ve had a few too many to drink order the Muses02??? I’d love to hear some suggestions as to what people think would be the best replacement in the $20 or under per device would be. Unless you think of something that is worth more than it’s cost like a Muses02 or a Burson Audio. I wouldn’t mind trying one of these exotic as long as people think it’s worth it.

I think I’ll keep it at there before this post gets too long and add to it as I make progress on the amp.

So first what are thought about upgrading the 2SC5200/2SA1943 to the MJL3281/MJL1302 and while we’re at it if anyone recommends upgrading the drivers or any of the 1815/1015 with lower noise devices. Have plenty KSA1220/KSC2690 and KSA1381/KSC3503, and more. Haven’t peeled at the spec sheet to see what would be a good drop in from the originals, and neither may perform as well as the originals. Just asking though.

Next would be the upgrade to the stock opamp. Would love to hear some suggestions.

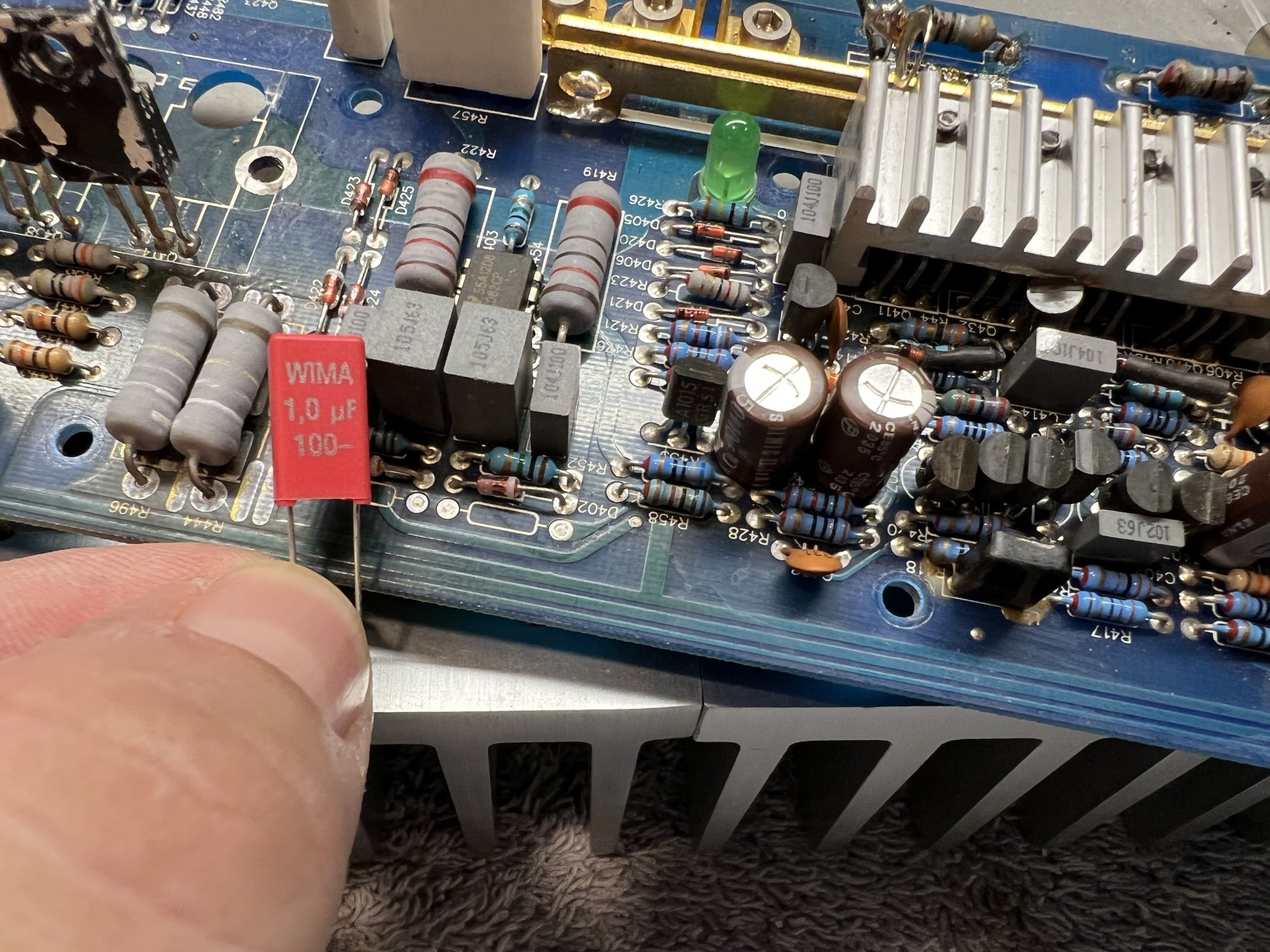

For the capacitors I’m using Panasonic FC and Elna Silmic II (or I have Nichicon FG, I have Muse too, but they’re physically too big). Oh which brings me to the film caps. They’re small and grey, unsure of brand or film type. Was thinking of swapping them all out with Wima polypropylene.

Unsure about resistors. They use your standard metal film. Any benefit to upgrading them as well? Basically looking for improvements that can be heard.

Thank you much!

Dan

I disassembled it and am currently working on the two amplifier boards. Nearly every capacitor on the board has very high ESR, like a 330uF 16v with and ESR of 27 ohms. Not sure why they choose to use garbage caps, but I find more bad caps in NAD gear than anything else lol. Other than that it seems to be a really, really nice dual mono design.

I was thinking that while I had it apart that maybe I should do some modifications to it, see if I might be able to get some audible improvement.

First: transistors, it uses decent signal transistors throughout the board, mostly being 2SC2240, 2SA970 and 2SC1815, 2SA1015. It also has a pair of 2SA1360 and a pair of 2SC3423. For drivers it uses 2SC4793 and 2SA1837, which I’ve read are actually pretty decent and make good drivers for the outputs I’m thinking of swapping to.

So it originally came with 4 2SC5200 and 4 2SA1943 in each channel. When asking about a transistor sub I learned that while this pair is okay (would have been a downgrade from what I wanted to sub), that a far superior pair would be the MJL3281 and MJL1302. I have several of each from Onsemi/Fairchild. Would this be a worthwhile improvement? Would there be an audible change noticed? Or would I just be wasting money and parts?

Next would be the opamp on each board. Currently uses TL082CP and thinking of an upgrade to maybe a an OPA device like 2134, maybe a 5532, maybe if I’ve had a few too many to drink order the Muses02??? I’d love to hear some suggestions as to what people think would be the best replacement in the $20 or under per device would be. Unless you think of something that is worth more than it’s cost like a Muses02 or a Burson Audio. I wouldn’t mind trying one of these exotic as long as people think it’s worth it.

I think I’ll keep it at there before this post gets too long and add to it as I make progress on the amp.

So first what are thought about upgrading the 2SC5200/2SA1943 to the MJL3281/MJL1302 and while we’re at it if anyone recommends upgrading the drivers or any of the 1815/1015 with lower noise devices. Have plenty KSA1220/KSC2690 and KSA1381/KSC3503, and more. Haven’t peeled at the spec sheet to see what would be a good drop in from the originals, and neither may perform as well as the originals. Just asking though.

Next would be the upgrade to the stock opamp. Would love to hear some suggestions.

For the capacitors I’m using Panasonic FC and Elna Silmic II (or I have Nichicon FG, I have Muse too, but they’re physically too big). Oh which brings me to the film caps. They’re small and grey, unsure of brand or film type. Was thinking of swapping them all out with Wima polypropylene.

Unsure about resistors. They use your standard metal film. Any benefit to upgrading them as well? Basically looking for improvements that can be heard.

Thank you much!

Dan

Last edited:

Oh, also wanted to ask this here. I asked over at audiokarma and nobody knows why they went this route.

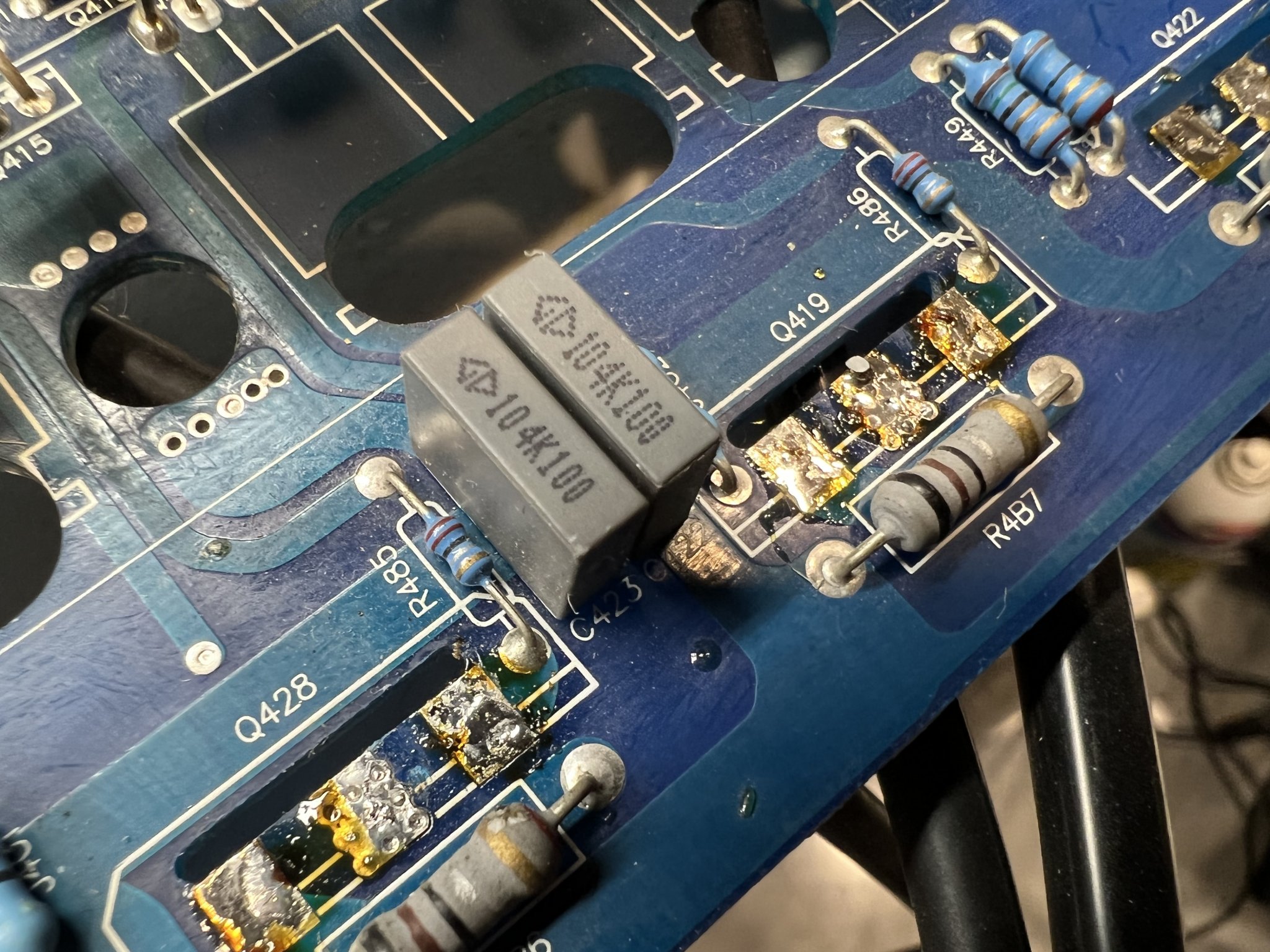

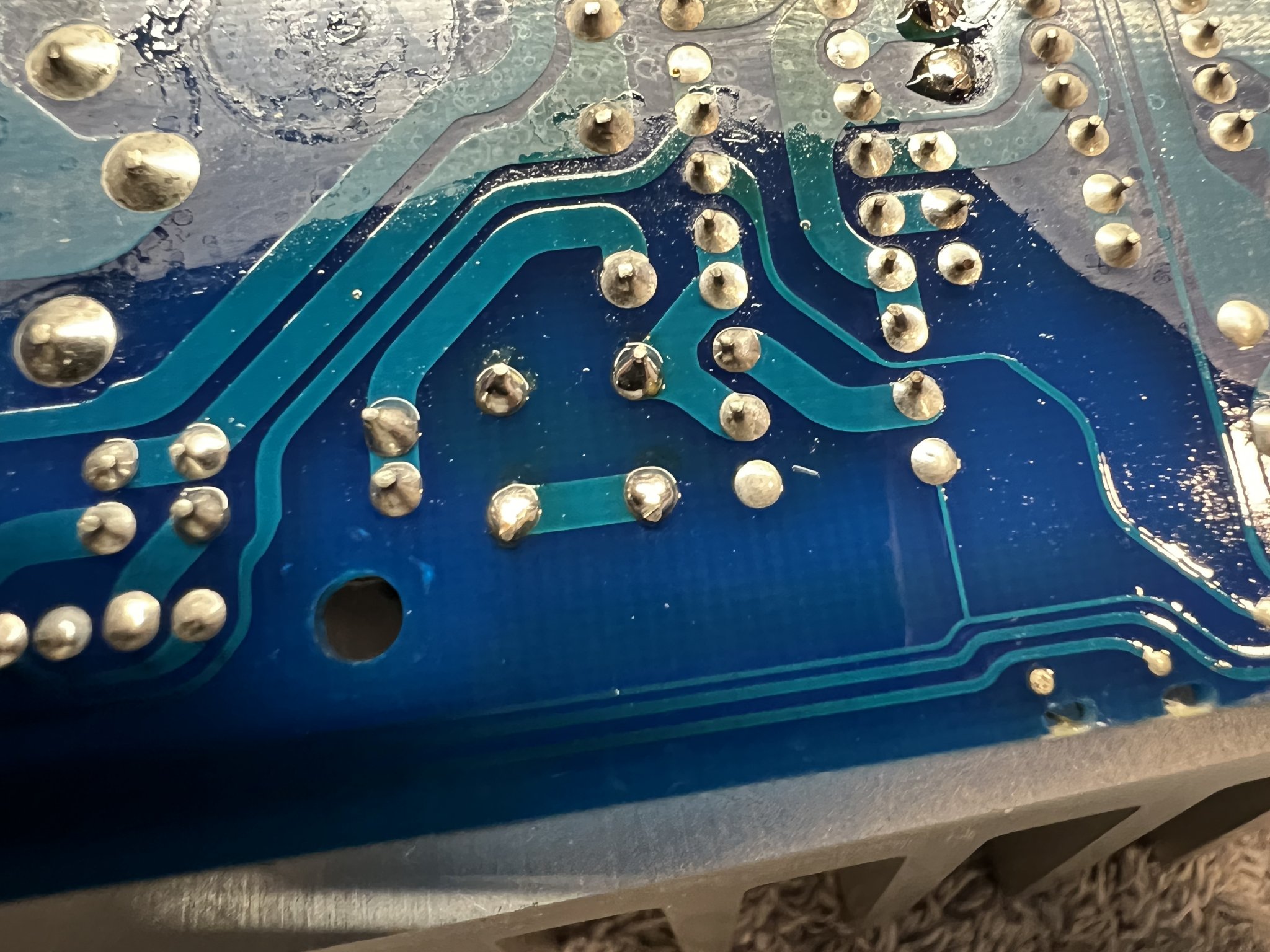

There are two 2.2uf 50v electrolytic caps on this board and they are wired in series, negatives connected together.

You can see the single trace there connecting the negatives, nothing else goes to that trace. Why would the choose to do it this way instead of using a single 1 uF 100v bipolar electrolytic or a film cap? There are already a few 1 uF 100v films on the board, so you know they had them. I’m confused on why they would choose this route, as I’m thinking of just throwing a 1uF 100v Wima polypropylene in there, but want to make sure I don’t mess anything up.

Dan

There are two 2.2uf 50v electrolytic caps on this board and they are wired in series, negatives connected together.

You can see the single trace there connecting the negatives, nothing else goes to that trace. Why would the choose to do it this way instead of using a single 1 uF 100v bipolar electrolytic or a film cap? There are already a few 1 uF 100v films on the board, so you know they had them. I’m confused on why they would choose this route, as I’m thinking of just throwing a 1uF 100v Wima polypropylene in there, but want to make sure I don’t mess anything up.

Dan

Upping an old amp is interesting because there are always "what were the designers thinking" situations. I am fixing a NAD C320 which has thousands of hours on it which means the polarized caps are suspect. I found a dried out one in the rectifier board.

It guess it is worthwhile to replace the electrolytics or any with limited lifetimes. I found the C320 is super hot internally because of poor ventilation. This compromises the mainboard components.

It guess it is worthwhile to replace the electrolytics or any with limited lifetimes. I found the C320 is super hot internally because of poor ventilation. This compromises the mainboard components.

NAD is a British design.

Not many new engineers in UK, and production now in China.

It never sold in the volumes of the Japanese competitors.

You will realize the design and overall quality are inferior to their competition.

Modifying it will simply overload the circuitry.

Leave it alone.

Not many new engineers in UK, and production now in China.

It never sold in the volumes of the Japanese competitors.

You will realize the design and overall quality are inferior to their competition.

Modifying it will simply overload the circuitry.

Leave it alone.

It seems it it in need of repair.

My advice is to dispose of it, and buy an old Japanese set.

NAD were mostly poorly designed, over hyped, and over expensive compared to Japanese. Best avoided.

Some models were considered good, but outside the UK it is an obscure brand.

Now it is owned by a firm in Canada, and made in China.

My advice is to dispose of it, and buy an old Japanese set.

NAD were mostly poorly designed, over hyped, and over expensive compared to Japanese. Best avoided.

Some models were considered good, but outside the UK it is an obscure brand.

Now it is owned by a firm in Canada, and made in China.

Yes, sometimes it is for the satisfaction, but the candidate must be worthy of our attention, and the result durable.

People keep old cars running, then find parts not available and mechanics have quite literally died.

Then a good car also has to be disposed of.

1961 'bug Fiat', front door hinged at B pillar, predecessor to the 1100.

Now sitting at a friend's place, he was going to give it to somebody, and that man died of Covid.

The mechanic was to be given the car, and he died.

He now has a new car, a SUV...so this is a sort of shelf queen for him.

I think I will tell him to advertise it as a rare collector's item, and get the best price for it.

Last edited:

While I’d agree that most NAD gear isn’t the greatest and it’s somewhat of a shell of what it used to be, I will say that it is quite different with this piece. It was their TOTL unit in the day and was around $3k usd.

And no I’m not going to dispose of it lol. That’s ridiculous, it only needs capacitors to be perfectly functioning again. Why would you think that even a logical suggestion???

I’ve repaired hundred of amps before this one and hopefully will repair hundreds more after so I will at the very least repair this one as well. I was just hoping to get ideas on getting the most out of it. That being better opamps or transistors. It’s already getting far better capacitors put into it, never understood why they use such garbage Chinese caps. If nobody has suggestions or thoughts on improving it I can always experiment.

Dan

And no I’m not going to dispose of it lol. That’s ridiculous, it only needs capacitors to be perfectly functioning again. Why would you think that even a logical suggestion???

I’ve repaired hundred of amps before this one and hopefully will repair hundreds more after so I will at the very least repair this one as well. I was just hoping to get ideas on getting the most out of it. That being better opamps or transistors. It’s already getting far better capacitors put into it, never understood why they use such garbage Chinese caps. If nobody has suggestions or thoughts on improving it I can always experiment.

Dan

The evolution was that the Chinese gradually became responsible for the design as well, starting as monkey grade contractors who did nothing but production.

Add to that bean counters, who wanted cheaper product that would last until warranty got over.

Just add the BOM, cut to 40 percent to get the real price at thousands purchase.

Then you will find this $3000 unit is maybe $500 worth.

Hence my comment that it is not very well made.

Saving 50 $ in caps is extreme cost cutting ...

Add to that bean counters, who wanted cheaper product that would last until warranty got over.

Just add the BOM, cut to 40 percent to get the real price at thousands purchase.

Then you will find this $3000 unit is maybe $500 worth.

Hence my comment that it is not very well made.

Saving 50 $ in caps is extreme cost cutting ...

Show me a $500 integrated amp that is equal to this amp.The evolution was that the Chinese gradually became responsible for the design as well, starting as monkey grade contractors who did nothing but production.

Add to that bean counters, who wanted cheaper product that would last until warranty got over.

Just add the BOM, cut to 40 percent to get the real price at thousands purchase.

Then you will find this $3000 unit is maybe $500 worth.

Hence my comment that it is not very well made.

Saving 50 $ in caps is extreme cost cutting ...

Dan

I said BOM...Bill Of Materials.

The total value of the parts used, not the list price.

$3000 list less 40% shop margin is $1800.

Less $300 in shipment, advertisement, warranty is $1500.

The importer paid the factory maybe $1200, and the factory would have bought pallets and trucks full of parts, at about 20-25% of what Mouser and their competitors charge.

So if Mouser charges you $2000 for what is in the amp, the factory would have paid about $500 for it.

I think you understand now.

Also, there was no need to put cheap caps in a premium product, but Bose and B&O have also been guilty of doing that.

Sadly, a general trend to increase profit, no matter if the customer finds out and does not come back...who opens them anyway, they get disposed off if they stop working.

No technicians available for the most part, nor parts.

The total value of the parts used, not the list price.

$3000 list less 40% shop margin is $1800.

Less $300 in shipment, advertisement, warranty is $1500.

The importer paid the factory maybe $1200, and the factory would have bought pallets and trucks full of parts, at about 20-25% of what Mouser and their competitors charge.

So if Mouser charges you $2000 for what is in the amp, the factory would have paid about $500 for it.

I think you understand now.

Also, there was no need to put cheap caps in a premium product, but Bose and B&O have also been guilty of doing that.

Sadly, a general trend to increase profit, no matter if the customer finds out and does not come back...who opens them anyway, they get disposed off if they stop working.

No technicians available for the most part, nor parts.

Last edited:

I would replace the bad electrolytic capacitors and whatever parts are needed to get amp back up and running and leave the rest alone. If you look at the schematic the opamp doesnt seem to be in the signal path so it will likely have no effect on the sound quality.

I would replace the series 2.2 uf electrolytic caps with a film cap if you can make it fit. I've tried back to back 10000 uf electrolytic caps as a speaker cap on a split supply amp, for speaker protection, and it made the sound a little funny on 1 vac output. That is where I listen to my amps most of the time, with 98 db 1w1m speakers. If you can't make the film cap fit I've used 1 uf 50 vac cog ceramic caps for the input cap without audible result. Input signals are < 2vac so the 50 volt rating straightens out some of the non-linearities of ceramic.

I would replace the electrolytic caps if you intend to keep the amp. I use industrial grade long life (>3000 hours service life) nichicon panasonic rubicon or kemet electrolytic caps, not pricey "audio" caps. See if that takes it out of protection mode. I find ebay prices are higher for NAD than some other brands, but selling old amps is not a real moneymaker if you value your time. Brands use short life electrolytic caps to trash the amp at a defined number of years and cause the owner to buy a new one. Lots of bad cap NADs on this forum, they apparently weren't designing for long life. I find Peavey design life to be about 20000 or up hours, tougher than most consumer market amps. If designers used epoxy seal electrolytic caps amps might last forever, which no marketing executive would want.

Film caps don't deteriorate so I'm not sure why a wima would be better than what is in there. Mylar film causes some minor distortion versus polyprophylene but there were hundreds of sources of polyprophylene besides wima.

Emitter follower output transistors don't really affect the sound so I would not replace the 2sa1943 2sc5200 if it didn't blow up the originals. With that huge heat sink would take a shorted wire to damage the output transistors.

Those driver & first stage transistors have enough Ft to not cause distortion, so I would leave them alone.

Agree op amp swapping is useful only for first stage in the sound path op amp. No benefit in the DC servo position. TL082 is slow and not prone to oscillate so modifications would be required to prevent oscillation in low noise substitutions like ST33078.

Resistors are not carbon comp so little benefit to swapping if they are metal film. If carbon film there is some slight benefit in thermal noise of metal film resistors 470 kohm or higher in value. Wirewound in the output stages is the standard technology and the slight inductance helps to prevent oscillations.

I would replace the electrolytic caps if you intend to keep the amp. I use industrial grade long life (>3000 hours service life) nichicon panasonic rubicon or kemet electrolytic caps, not pricey "audio" caps. See if that takes it out of protection mode. I find ebay prices are higher for NAD than some other brands, but selling old amps is not a real moneymaker if you value your time. Brands use short life electrolytic caps to trash the amp at a defined number of years and cause the owner to buy a new one. Lots of bad cap NADs on this forum, they apparently weren't designing for long life. I find Peavey design life to be about 20000 or up hours, tougher than most consumer market amps. If designers used epoxy seal electrolytic caps amps might last forever, which no marketing executive would want.

Film caps don't deteriorate so I'm not sure why a wima would be better than what is in there. Mylar film causes some minor distortion versus polyprophylene but there were hundreds of sources of polyprophylene besides wima.

Emitter follower output transistors don't really affect the sound so I would not replace the 2sa1943 2sc5200 if it didn't blow up the originals. With that huge heat sink would take a shorted wire to damage the output transistors.

Those driver & first stage transistors have enough Ft to not cause distortion, so I would leave them alone.

Agree op amp swapping is useful only for first stage in the sound path op amp. No benefit in the DC servo position. TL082 is slow and not prone to oscillate so modifications would be required to prevent oscillation in low noise substitutions like ST33078.

Resistors are not carbon comp so little benefit to swapping if they are metal film. If carbon film there is some slight benefit in thermal noise of metal film resistors 470 kohm or higher in value. Wirewound in the output stages is the standard technology and the slight inductance helps to prevent oscillations.

Last edited:

I see.I said BOM...Bill Of Materials.

The total value of the parts used, not the list price.

$3000 list less 40% shop margin is $1800.

Less $300 in shipment, advertisement, warranty is $1500.

The importer paid the factory maybe $1200, and the factory would have bought pallets and trucks full of parts, at about 20-25% of what Mouser and their competitors charge.

So if Mouser charges you $2000 for what is in the amp, the factory would have paid about $500 for it.

I think you understand now.

Also, there was no need to put cheap caps in a premium product, but Bose and B&O have also been guilty of doing that.

Sadly, a general trend to increase profit, no matter if the customer finds out and does not come back...who opens them anyway, they get disposed off if they stop working.

No technicians available for the most part, nor parts.

Yeah I just fixed a “premium” Bowers and Wilkins amplified speaker and was $800 and they absolute garbage electrolytics they use puzzles me. I guess if it gets them past the warranty window. Wouldn’t you rather spend the few extra dollars for each unit to put in premium Japanese caps from Panasonic or Nichicon so that the unit doesn’t fail 5 years down the road and sour your name?

Dan

I would replace the bad electrolytic capacitors and whatever parts are needed to get amp back up and running and leave the rest alone. If you look at the schematic the opamp doesnt seem to be in the signal path so it will likely have no effect on the sound quality.

Thank you, yes I did realize that it isn’t in the signal path, plus they used some OPA2134s in the amp, so I’m sure if it was critical they would have used them here as well. So as of now that is the plan, replace the electrolytics and get it going. Do you have any thoughts on replacing the films with Wima Polypropylenes? Worth the effort or forget it. Do you know what brand they are? I imagine if they used garbage electrolytics they’d use garbage film.

Dan

I would replace the series 2.2 uf electrolytic caps with a film cap if you can make it fit. I've tried back to back 10000 uf electrolytic caps as a speaker cap on a split supply amp, for speaker protection, and it made the sound a little funny on 1 vac output. That is where I listen to my amps most of the time, with 98 db 1w1m speakers. If you can't make the film cap fit I've used 1 uf 50 vac cog ceramic caps for the input cap without audible result. Input signals are < 2vac so the 50 volt rating straightens out some of the non-linearities of ceramic.

I would replace the electrolytic caps if you intend to keep the amp. I use industrial grade long life (>3000 hours service life) nichicon panasonic rubicon or kemet electrolytic caps, not pricey "audio" caps. See if that takes it out of protection mode. I find ebay prices are higher for NAD than some other brands, but selling old amps is not a real moneymaker if you value your time. Brands use short life electrolytic caps to trash the amp at a defined number of years and cause the owner to buy a new one. Lots of bad cap NADs on this forum, they apparently weren't designing for long life. I find Peavey design life to be about 20000 or up hours, tougher than most consumer market amps. If designers used epoxy seal electrolytic caps amps might last forever, which no marketing executive would want.

Film caps don't deteriorate so I'm not sure why a wima would be better than what is in there. Mylar film causes some minor distortion versus polyprophylene but there were hundreds of sources of polyprophylene besides wima.

Emitter follower output transistors don't really affect the sound so I would not replace the 2sa1943 2sc5200 if it didn't blow up the originals. With that huge heat sink would take a shorted wire to damage the output transistors.

Those driver & first stage transistors have enough Ft to not cause distortion, so I would leave them alone.

Agree op amp swapping is useful only for first stage in the sound path op amp. No benefit in the DC servo position. TL082 is slow and not prone to oscillate so modifications would be required to prevent oscillation in low noise substitutions like ST33078.

Resistors are not carbon comp so little benefit to swapping if they are metal film. If carbon film there is some slight benefit in thermal noise of metal film resistors 470 kohm or higher in value. Wirewound in the output stages is the standard technology and the slight inductance helps to prevent oscillations.

Wow, thank you, that covers pretty much everything. I’ll be swapping the back to back electrolytics with film.

As far as the film caps in there currently, concern comes from the possibility of them being garbage quality just as the electrolytics are. Only reason I suggest Wima is because I have a few thousand of various values.

No intentions of selling the amp, plan is to fix it and use it. When working it’s a wonderful sounding and powerful amplifier.

Overall sounds like it’s a properly designed amp and not really much I can do to improve on it.

Dan

Garbage film caps arent as likely as garbage electrolytics. Since they are dry by nature they can’t dry out and go bad. If cheaply made the worst that could happen is going microphonic, not failing entirely - unless it dies from overvoltage. That’s not going to happen in a gentle SS amp application. You can usually see that a film cap is poorly wound - it will be all lumpy and compressible between two fingers, or it will audibly sing with a large AC signal. Anything like that should go. Just don’t buy no-names, and polypropylene is preferable to basic mylar.

It doesn’t quite look like the costcutter that something like the 3020 is. Crappy electrolytics have been known to find their way into just about everything from time to time, even stuff with $10k price tags. Fortunately for us, we usually have a couple bins of Nichicons on hand….

It doesn’t quite look like the costcutter that something like the 3020 is. Crappy electrolytics have been known to find their way into just about everything from time to time, even stuff with $10k price tags. Fortunately for us, we usually have a couple bins of Nichicons on hand….

- Home

- Amplifiers

- Solid State

- Squeezing the most performance from NAD M3 as I can, switching to different outputs, is it worth it?