Hello guys,

I wanted to share my experience on building few sound diffusors 2 years ago.

We know they can be very expensive from a shop if you want to cover enough, but can also be very ugly if you diy while not so versed in woodworking, like me.

Well I like wood working but it's just very hard to get the clean finish I want, too impatient and I just have basic tools.

In my previous room I had a mix of Decware, ATSacoustics and Giks with great effect.

Money was not a problem at that time, but now the room is twice the size and I really needed a different solution.

Plus I would then be able to define the right frequencies and go a little lower with more depth.

So I wanted to find a good compromise, cheap, fast, easy, while good looking enough.

Re-using an existing and clean looking box was a solution.

But it's not only the box, I also needed to build the wells and fins with what I could find around at a good price (right when wood price started to fly up).

Meaning lumbers and mdf panels with the right dimensions with minimal cuts for the boxes I could find.

Plus I wanted the process to be simple and repeatable, tolerant to human errors, so they would all look and behave alike.

So the lumber cuts/wells dimensions needed to be integer, not too hard to repeat.

Started by looking around all shops for simple box, wood preferably but all kind really.

Then based on theirs size I would calculate the right dimensions for the fins and the wells.

Took a lot of back and forth but I ended with an ikea besta, 60x64x20cm, that exists in black or tan.

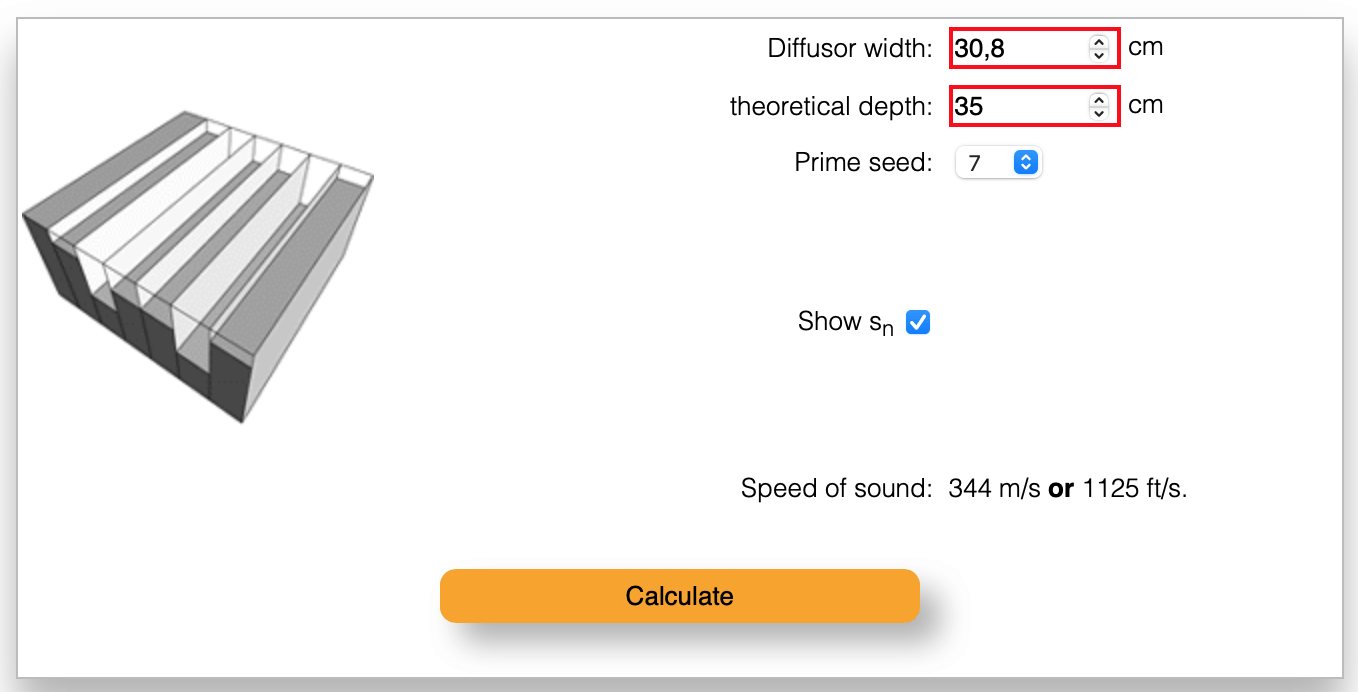

It allowed a double symmetric QRD n7 with 38mm wells and 6mm fins with an F low around 350Hz and an F high around 4700Hz, perfect for my OB midranges.

See calc:

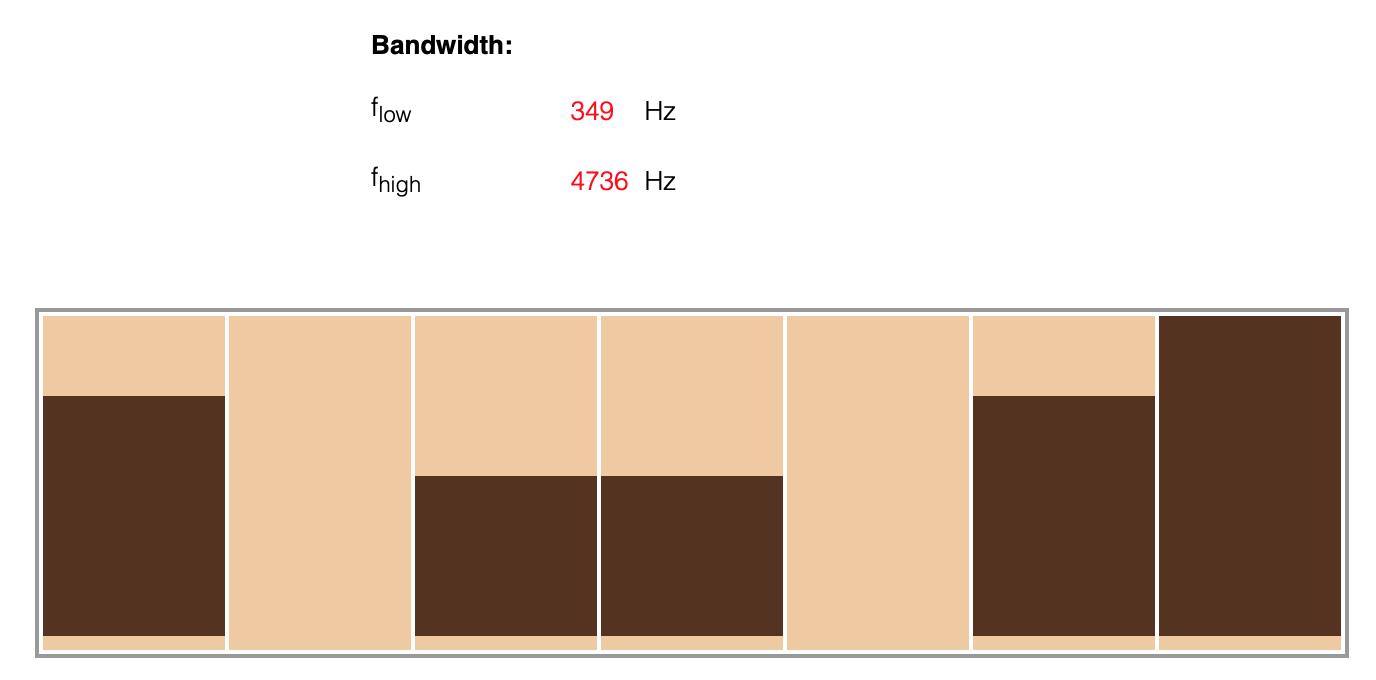

Here only half:

Wells from left to right, in mm: 20 box left wall, 12x6 fins + 13x38 wells, 20 box right wall

Depths: 0 - 50 - 200 - 100 - 100 - 200 - 50 - 0 - 50 - 200 - 100 - 100 - 200 - 50 - 0

The 0.8mm added in width were need to include the fins thickness in the wells width calculation.

You will later notice it's not an exact symmetry since side walls/half wells are 20mm and the central one is 50mm with its 2 side fins.

I believe the effect is minimal, and it was just too hard to build without 2 fins on the central one to hold it.

Also once the boxes are stacked there is a little gap between them, so it kind of repeat the width of the central one. Details details...

Price-wise, it was quite some time ago so I don't have all details, but I remember calculating something like 40 euros per diffuser.

I just checked the besta price, now at 35 euros, they were for sure cheaper at that time, I think I remember 20 euros but maybe I’m wrong.

Plus I got more than half in the demo/used corner ready to go.

For the lumbers I had to visit few shops as the real dimensions can differ of their listed spec.

I started with 8 boxes but decided for more after and was lucky enough to find lots with the exact same dimensions as the lumbers I see now are not consistent.

Mdf in 6mm is cheap, especially with the big panel 250/120cm, I didn't try thinner as it was too flimsy.

Big panels are just a pain to cut without proper table but it saved quite a bit I remember.

Process (no pics sorry I didn't think of that):

1 - build the box, without the back panel, doesn't need added glue it's sturdy enough

2 - cut all lumbers to 58cm length, the internal height of the box. Trial and error but 1mm variation is ok. remove the non straight enough ones.

3 - cut mdf into 20x58cm, box height + a little more depth for some to allow glueing the deepest wells at 20cm.

I could have saved even more $ by optimising the cuts here but it was just easier to cut them all at the same dimensions, roughly. Their height is important though of course, needs a 1mm precision, and a clean "front" cut, the back one can be ugly.

4 - dry mount, here I'll try to describe what I did:

Put the box flat on the table, final front facing up.

Then use 13 spare wells (or cut leftover) with the 12 final fins to fit everything first, the wells deep to touch the table, it can be be tight so be careful to not bend the fins, use another lumber to push them.

Then I'd stack more spare wells to define the final depth (I used 25x38, so stacking them would give me the right calculated depth 5/10/20 etc, another place to save money here with thinner lumbers but it was easier)

So row 1: 5 stacked wells + 1 final well gives a final front depth of 5cm, 20-(6x2.5).

Row 2: just 2/3 spare wells to keep the fins in place for now.

Row 3&4: 3 spare wells + 1 final well gives a final front depth of 10cm, 20-(4x2.5).

Etc for other rows.

5- glueing

Once all the stacks are done, I will glue the final wells on top, pushing them to fit tight.

I wasn't sure the glue would be ok on the box surface that is plastic covered, but it was fine it worked.

Once all final wells are glued, put the box carefully on its base, and glue the 2 wells at the back for the deepest depths (row 2&5).

Placed by hand is enough, just make sure you get the 20cm depth in front.

keep drying 1 day.

6 - spare removal

Once all dried you can remove all spares and use them for the next diffuser.

I used to do 1 or 2 a day and it took less than 30min for the last ones.

Only one was not sturdy enough at the end, due to too short fins, added glue from behind fixed it.

Results:

Boxes are solid while still light, can be stacked 3 or more, and moved around safely.

I've just built a base structure as my ground is not flat.

Once all fins are glued they stay in place, but don't push too hard on them.

With the leds the effect is I think pretty cool, lovely at night.

I need to dig-in to find some "before" measurements, I have so many I'm not sure I’ll find the right ones.

Not even sure it will be visible there, but I do prefer with 9 per side for sure, while 4 per side already had an effect.

The room is rectangular, and I use it in its width, so it helped a lot to get back some depth in the soundstage, virtually increased it.

Now I have to work on bass traps...

I wanted to share my experience on building few sound diffusors 2 years ago.

We know they can be very expensive from a shop if you want to cover enough, but can also be very ugly if you diy while not so versed in woodworking, like me.

Well I like wood working but it's just very hard to get the clean finish I want, too impatient and I just have basic tools.

In my previous room I had a mix of Decware, ATSacoustics and Giks with great effect.

Money was not a problem at that time, but now the room is twice the size and I really needed a different solution.

Plus I would then be able to define the right frequencies and go a little lower with more depth.

So I wanted to find a good compromise, cheap, fast, easy, while good looking enough.

Re-using an existing and clean looking box was a solution.

But it's not only the box, I also needed to build the wells and fins with what I could find around at a good price (right when wood price started to fly up).

Meaning lumbers and mdf panels with the right dimensions with minimal cuts for the boxes I could find.

Plus I wanted the process to be simple and repeatable, tolerant to human errors, so they would all look and behave alike.

So the lumber cuts/wells dimensions needed to be integer, not too hard to repeat.

Started by looking around all shops for simple box, wood preferably but all kind really.

Then based on theirs size I would calculate the right dimensions for the fins and the wells.

Took a lot of back and forth but I ended with an ikea besta, 60x64x20cm, that exists in black or tan.

It allowed a double symmetric QRD n7 with 38mm wells and 6mm fins with an F low around 350Hz and an F high around 4700Hz, perfect for my OB midranges.

See calc:

Here only half:

Wells from left to right, in mm: 20 box left wall, 12x6 fins + 13x38 wells, 20 box right wall

Depths: 0 - 50 - 200 - 100 - 100 - 200 - 50 - 0 - 50 - 200 - 100 - 100 - 200 - 50 - 0

The 0.8mm added in width were need to include the fins thickness in the wells width calculation.

You will later notice it's not an exact symmetry since side walls/half wells are 20mm and the central one is 50mm with its 2 side fins.

I believe the effect is minimal, and it was just too hard to build without 2 fins on the central one to hold it.

Also once the boxes are stacked there is a little gap between them, so it kind of repeat the width of the central one. Details details...

Price-wise, it was quite some time ago so I don't have all details, but I remember calculating something like 40 euros per diffuser.

I just checked the besta price, now at 35 euros, they were for sure cheaper at that time, I think I remember 20 euros but maybe I’m wrong.

Plus I got more than half in the demo/used corner ready to go.

For the lumbers I had to visit few shops as the real dimensions can differ of their listed spec.

I started with 8 boxes but decided for more after and was lucky enough to find lots with the exact same dimensions as the lumbers I see now are not consistent.

Mdf in 6mm is cheap, especially with the big panel 250/120cm, I didn't try thinner as it was too flimsy.

Big panels are just a pain to cut without proper table but it saved quite a bit I remember.

Process (no pics sorry I didn't think of that):

1 - build the box, without the back panel, doesn't need added glue it's sturdy enough

2 - cut all lumbers to 58cm length, the internal height of the box. Trial and error but 1mm variation is ok. remove the non straight enough ones.

3 - cut mdf into 20x58cm, box height + a little more depth for some to allow glueing the deepest wells at 20cm.

I could have saved even more $ by optimising the cuts here but it was just easier to cut them all at the same dimensions, roughly. Their height is important though of course, needs a 1mm precision, and a clean "front" cut, the back one can be ugly.

4 - dry mount, here I'll try to describe what I did:

Put the box flat on the table, final front facing up.

Then use 13 spare wells (or cut leftover) with the 12 final fins to fit everything first, the wells deep to touch the table, it can be be tight so be careful to not bend the fins, use another lumber to push them.

Then I'd stack more spare wells to define the final depth (I used 25x38, so stacking them would give me the right calculated depth 5/10/20 etc, another place to save money here with thinner lumbers but it was easier)

So row 1: 5 stacked wells + 1 final well gives a final front depth of 5cm, 20-(6x2.5).

Row 2: just 2/3 spare wells to keep the fins in place for now.

Row 3&4: 3 spare wells + 1 final well gives a final front depth of 10cm, 20-(4x2.5).

Etc for other rows.

5- glueing

Once all the stacks are done, I will glue the final wells on top, pushing them to fit tight.

I wasn't sure the glue would be ok on the box surface that is plastic covered, but it was fine it worked.

Once all final wells are glued, put the box carefully on its base, and glue the 2 wells at the back for the deepest depths (row 2&5).

Placed by hand is enough, just make sure you get the 20cm depth in front.

keep drying 1 day.

6 - spare removal

Once all dried you can remove all spares and use them for the next diffuser.

I used to do 1 or 2 a day and it took less than 30min for the last ones.

Only one was not sturdy enough at the end, due to too short fins, added glue from behind fixed it.

Results:

Boxes are solid while still light, can be stacked 3 or more, and moved around safely.

I've just built a base structure as my ground is not flat.

Once all fins are glued they stay in place, but don't push too hard on them.

With the leds the effect is I think pretty cool, lovely at night.

I need to dig-in to find some "before" measurements, I have so many I'm not sure I’ll find the right ones.

Not even sure it will be visible there, but I do prefer with 9 per side for sure, while 4 per side already had an effect.

The room is rectangular, and I use it in its width, so it helped a lot to get back some depth in the soundstage, virtually increased it.

Now I have to work on bass traps...

Thanks StigErik, it was fun to build, and I love looking around at this shop for quick and not so dirty simple hacks.

ex:

I think I read an article about the fins, improving the effect on lower frequencies, while detrimental if too thick.

I’d like to find a similar trick for a skyline diffuser now, to fill the gap in between each wall, if only visually.

for now I reused the back panels in a triangle shape, only visual effect as it probably doesn’t do anything great to the sound:

lighten concrete is a good option here, based on a mold from a first wood version.

Maybe later...

ex:

I think I read an article about the fins, improving the effect on lower frequencies, while detrimental if too thick.

I’d like to find a similar trick for a skyline diffuser now, to fill the gap in between each wall, if only visually.

for now I reused the back panels in a triangle shape, only visual effect as it probably doesn’t do anything great to the sound:

lighten concrete is a good option here, based on a mold from a first wood version.

Maybe later...