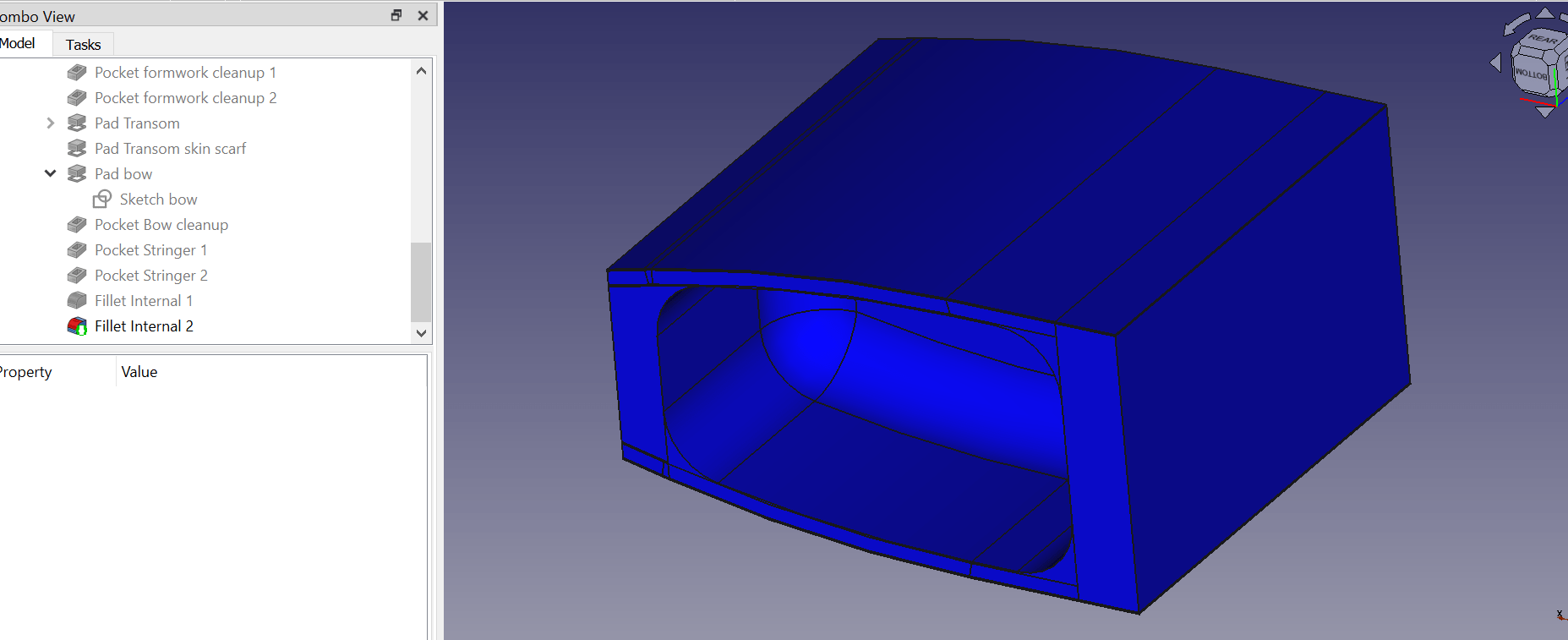

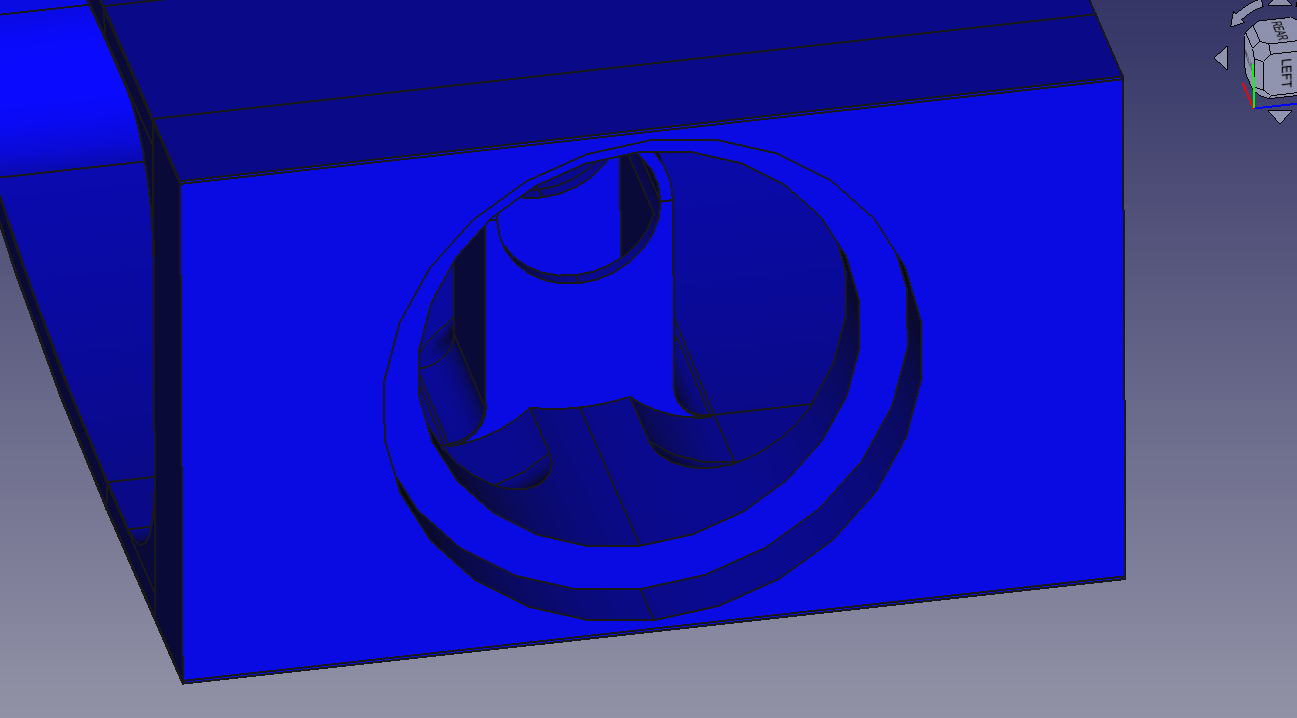

The fillets in the previous update do not meet my spec in this area. So I had to take the model back to the point in time of creating the back panel. There is a limitation in FreeCAD that I had to find a work around for and in this case turning the back panel to 30mm from 20mm thickness did the trick. Now I can set 40mm fillets instead of 9mm. The updated pic shows the new internal fillets

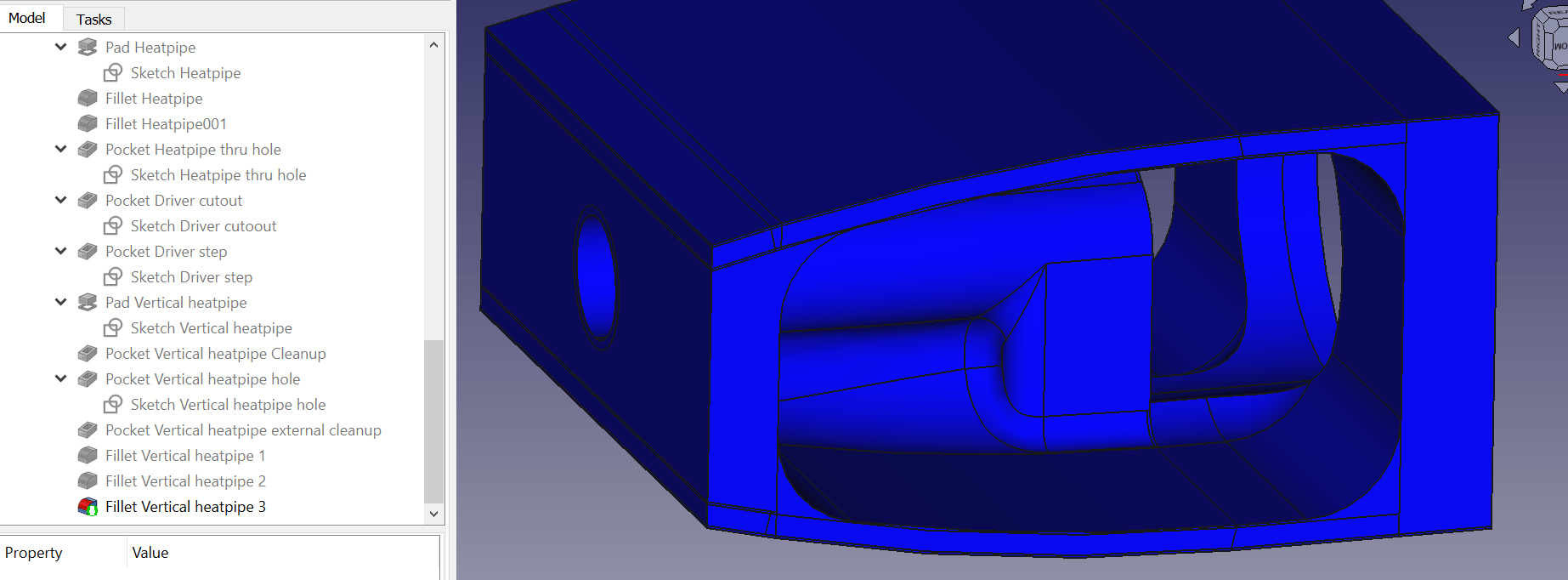

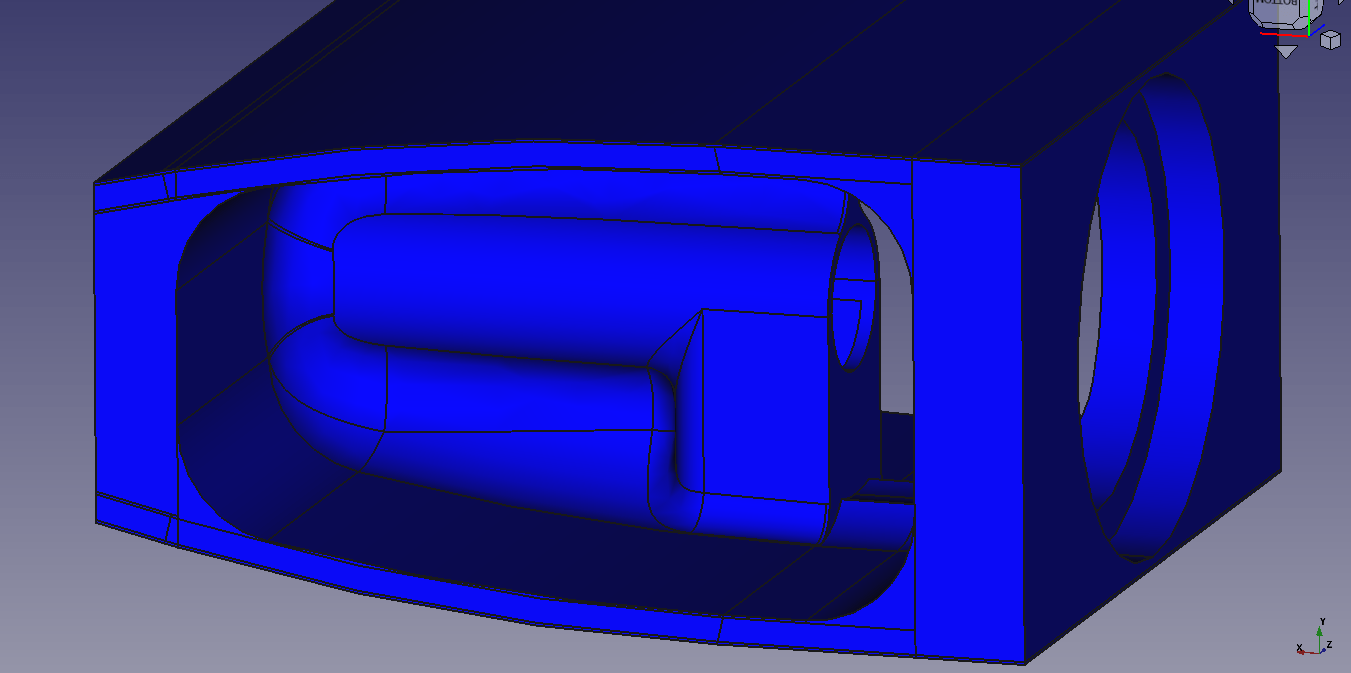

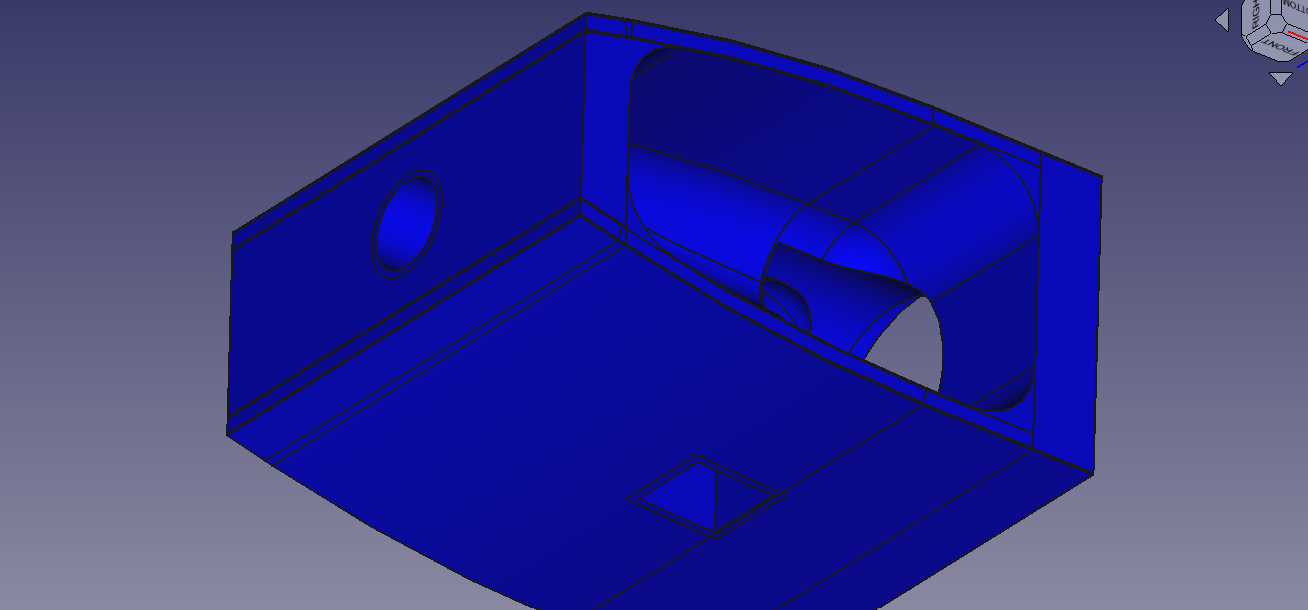

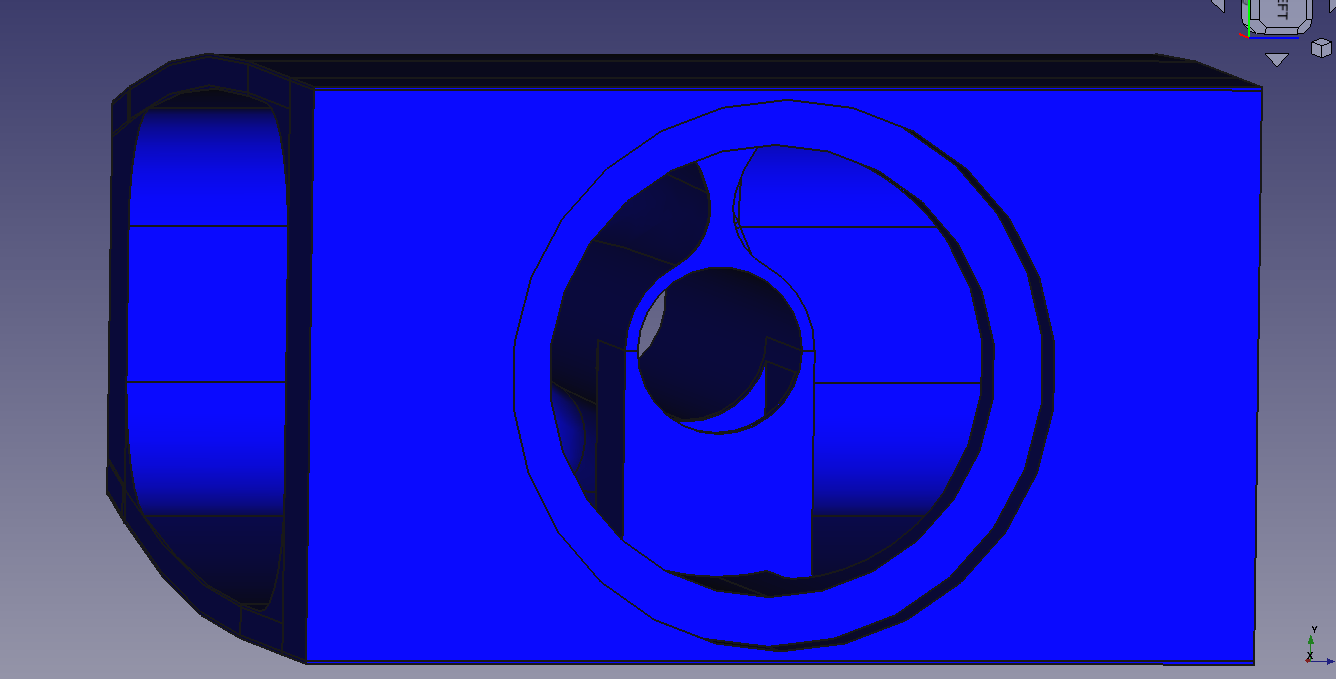

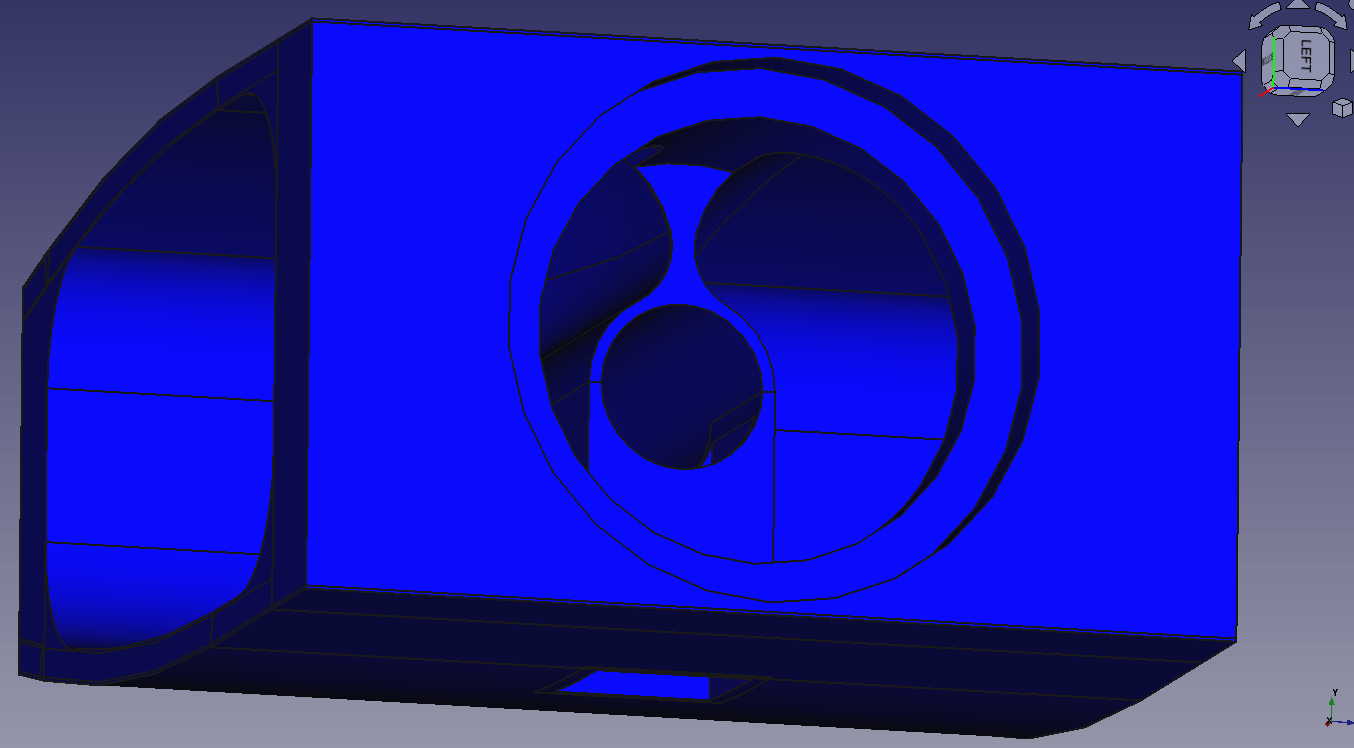

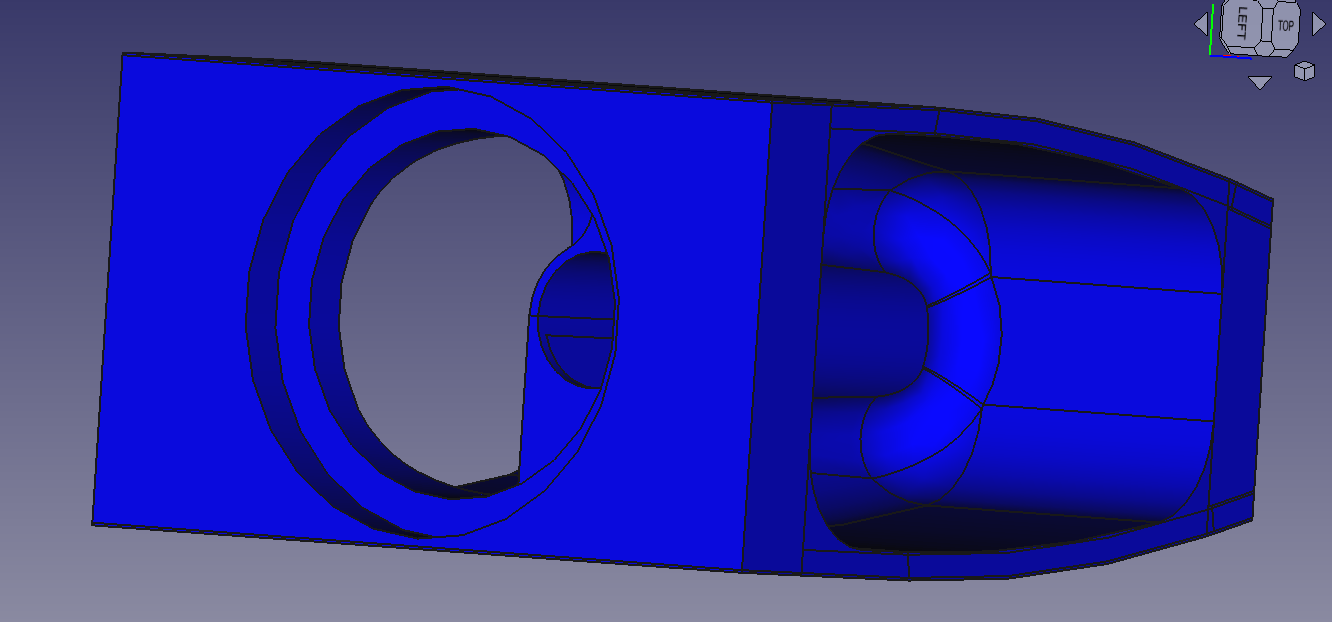

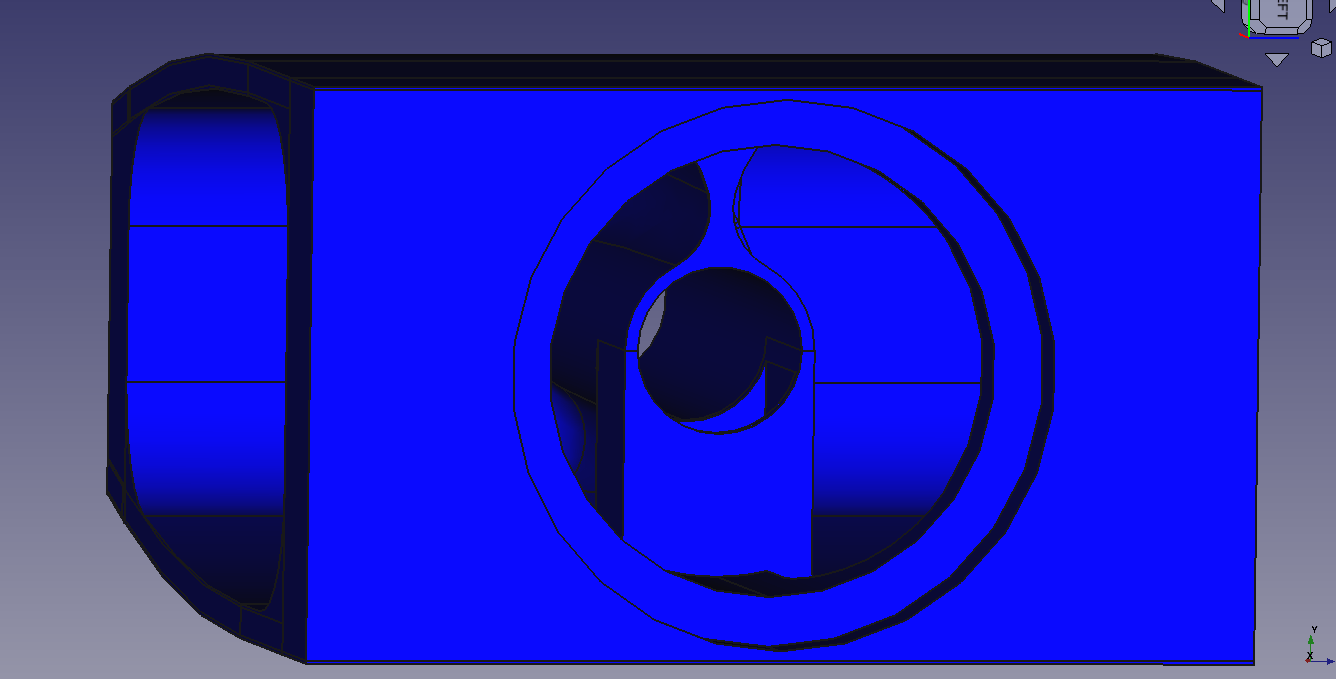

Internals for the speaker sections are mostly modelled now. The following pics show how the 90 degree bend in the heatpipe is formed, how the fillets merge with the pipe and internal walls and how the active driver cutout and step recess is formed. I have chosen a 20mm rebate step instead of flush to allow some depth for excursion

No, this issue is not a flaw in the program. That's how the fillets work. When you select an edge and fillet that, a pair of lines in the model are formed at the fillet widths. The lines from another fillet cannot superimpose or pass over. One line can approach another to any decimal point but never the whole number or beyond. When I curved the cab sides using fillets, a line got set near the rear inside curve. New fillet on the inside corner got limited to 9.999999999mm as the line was 10mm away from the corner edge line. I resolved this by going back to the back panel that I had extruded through the cab. This was going to be 20mm bamboo panel. By extending the width to 30mm, I managed to extrude it over that line and swallow it up. The new inside corner edge now has moved 10mm and no longer restricted by any lines from previous fillet and I could now set my 40mm radius work out from my scantlings for this projectHave you reported that issue to the developers (freecad)

Now that I am aware of this limitation, I can use it better. Next one that I draw like this will have all these initial lines placed inside points of future extrusions and carves. I hope this makes sense

The FreeCAD app is very capable but very chaotic in interface. It seems to be made up of modules (workbenches) coded by different folks. The modules aren't very consistent with each other. I think I have worked out the parts design bench fairly well now but can really feel the combined weight of these limitations for prototyping. This is a program for drawing an already designed item. Have a look at the FreeCAD templates done by other members for flat panel speaker boxes. The use of spreadsheet and all that is a very mature process for FreeCAD

Unfortunately, the only progie that seems aimed at prototyping is SolidWorks. It really is worth the money they are asking, and my hobby is important enough to me to work towards this

That's it, the rear panel is complete and so is the speaker section of this cab. Onto the electronics bay now. Version two electronics bay will be fairly roomy. At the moment, I am leaning towards an FFA001 module to drive the mains and FFA002 channels for the subs DVC. Two pairs of custom banana outs for the mains. Stereo XLR ins from the mixer and a DSP based xover inside. A neat addition will be a pair of banana sets for switching the internal amp to drive a larger external passive sub

One option here is to just print this whole thing. My scantlings allow for an all printed sandwich, and v2 allows for it. The electronics bay can be printed on its own and attached. The scantlings for print is what I have worked out for my marine parts. The spec is PETG as filament done at 240 degrees Celsius (80mms on a CR6-MAX) with 30% infill and 2mm walls (5 lines at .40mm with stock CR6-MAX). There will be a lot of support material used. Forget about printing in sections and gluing together. That's not for PETG. This can be printed in PLA and glued together but not for mobile use and must be painted well to slow down breakdown over time. I have no experience printing ABS so cannot comment on that. The most effective way to build this cab is manually building the sandwich using a mix of machined and printed parts and this will the method used

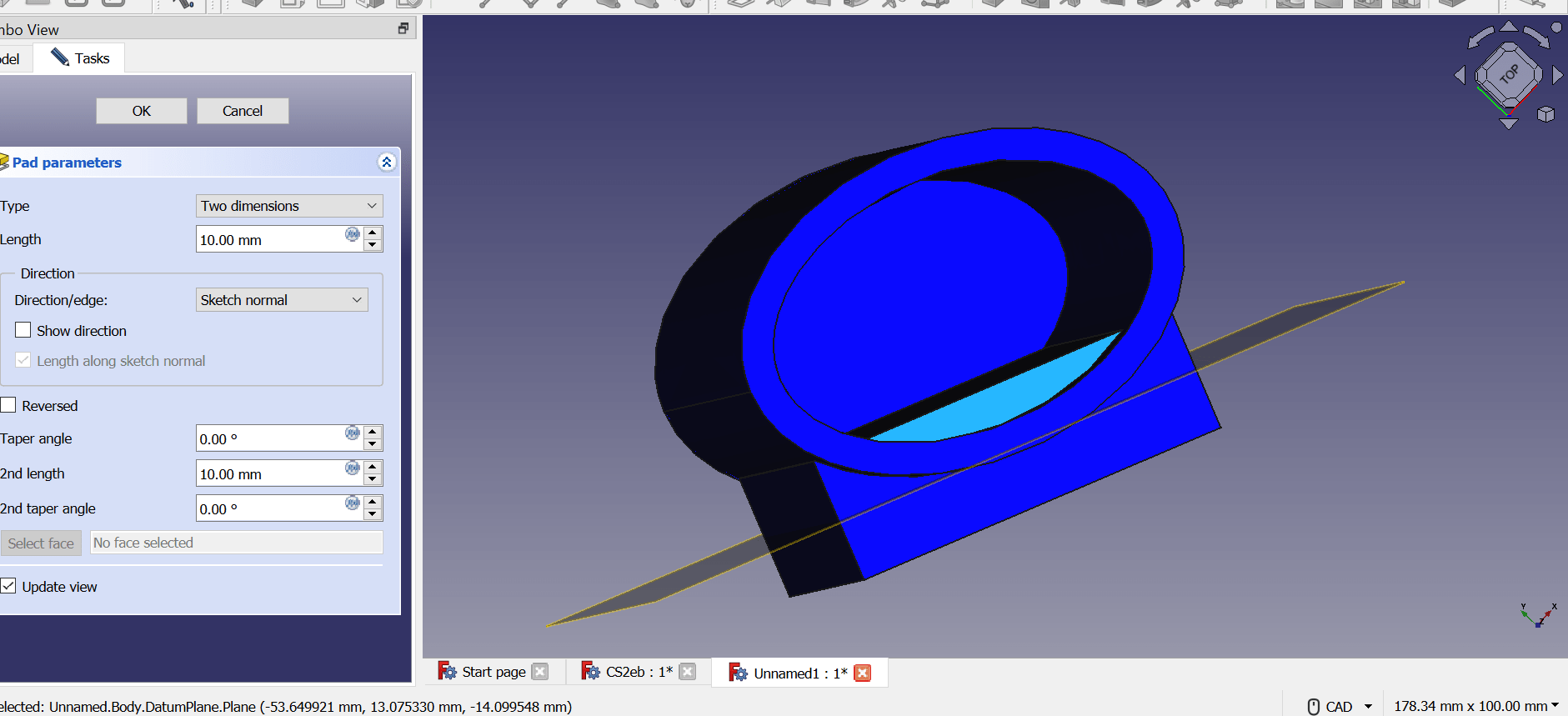

After a day of headbutting with FreeCAD. This is how far back I need to cut the model back to start the electronics bay feature. This time I think it's a program bug, as the extrude to a face function does not work as expected. I have extruded to a curved face before, so didn't expect it to not work

Doing it at this stage is super easy though. What I will do is save this as a new file, create the electronics bay and then carve away the cab to end up with a two part model

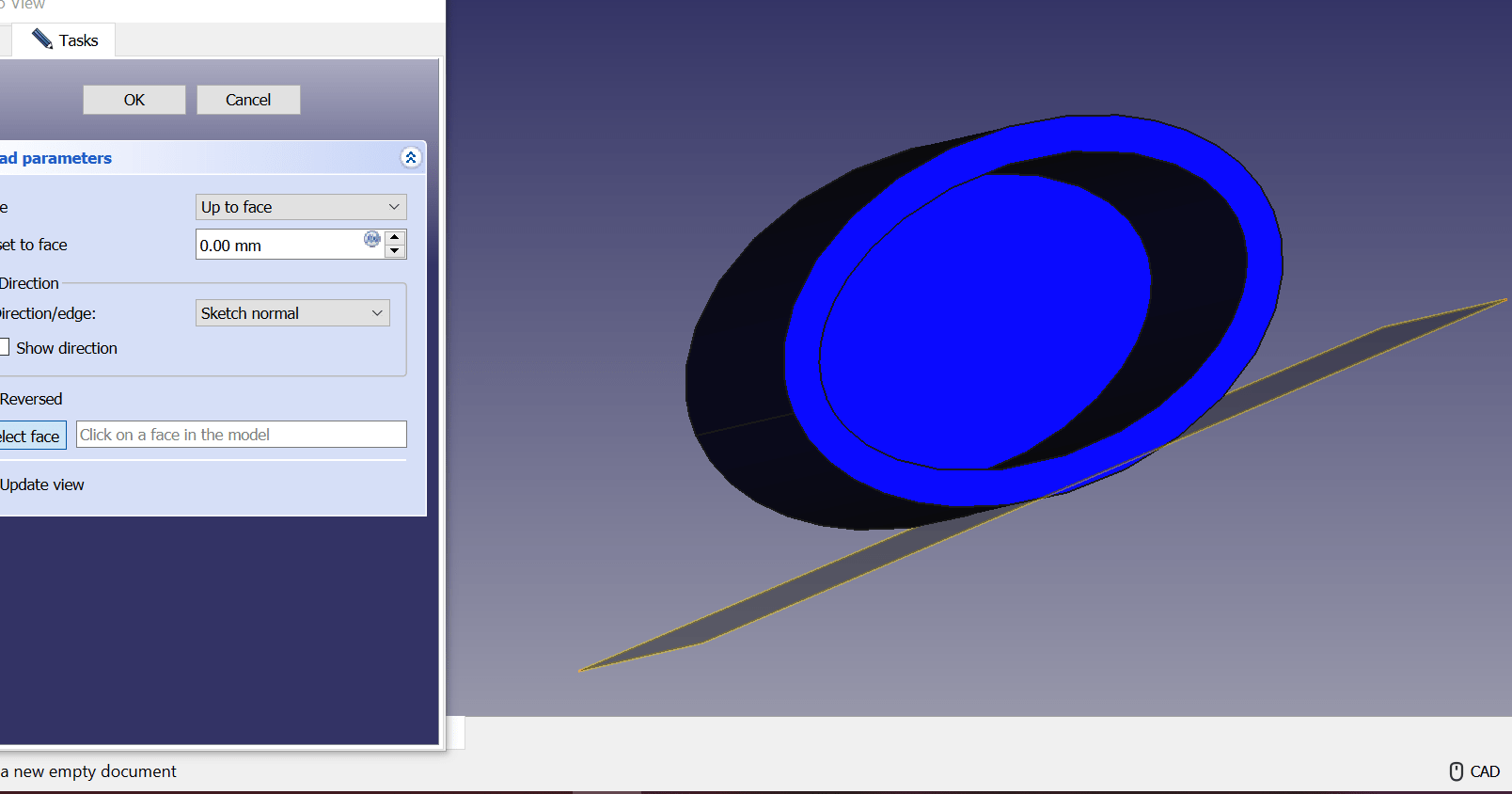

Studying this further as maybe I am not using this function correctly. Made a test case curved panel and extruded to it. A regular extrusion using the dimension option works as expected. Creates a slab and the highlighted face gets carved away next. I'll use this way to create individual side, fore and aft panels for the bay

Extruding by using up to face and both checked and unchecked for the reverse box does nothing

I will explore this some more and see about sending a link to this message

Extruding by using up to face and both checked and unchecked for the reverse box does nothing

I will explore this some more and see about sending a link to this message

I have been sitting in front of the screen and looking at this toy robot head, and It's still not growing on me

Now I remember reading this about 59 years ago, but don't remember why you started designing a speaker to like it..

Now we have a name for v2, TRR, the runaway robot!Now I remember reading this about 59 years ago, but don't remember why you started designing a speaker to like it..

Really not happy with the way the electronics bay looks sitting under like that. Lets have one go at flipping the project axis to the ones for the satellites (Cubs, this will be part of a 2.1 system). I'll convert the reflex port on the satellite cab that shares dimensions with the sub. Will convert that port to an electronics bay and design in the dual PR hard points

A benefit would be that it will open up the PR option for the satellites too. I have already applied the lessons learnt from v1 and v2 re the program limitations and prepared the base body from scratch for v3. Pretty excited about having a new base with very clean lines, removing those elements that would present the limitations at a later stage. I also want to see if I can get this model finished today

Showing her clean lines and new stance. Due to the vertical axis, v3 will be more placement flexible but won't look as good sitting next to a 'baithak' crew providing an electronic kick support to a harmonium, dhantal, dholak, manjeera and kartal ensemble performing seated on the porch floor. Presentation is important, and I might also build a v1 for floorplay

I forgot to ask, why do you have the port directly centered behind the driver instead of the opposite end of the driver?

As matter of fact, why not move the driver to the left side and start the port on the right side of the enclosure or vice versa?

You might be able to have the port exit on the same panel as the driver.

As matter of fact, why not move the driver to the left side and start the port on the right side of the enclosure or vice versa?

You might be able to have the port exit on the same panel as the driver.

That is not a reflex port. It's an extension of the pole vent with a 90 bend at the magnet. Side entry and rear active fan exhaust. This is a passive radiator cab fed 600wrms and no where for the heat buildup to go. That designed in heatpipe is isolated from the driver air volume and always keeps moving fresh air at the vent. If this cab was built as reflex, the port would be a slot type at one of the ends and bend at the rear panel if longer than internal depth. I am thinking of using this potential port area for mounting the electronics. Keep in mind that this cab is just over half a cubic foot external and fits a driver with 15mm xmax, dual passive radiators, DSP board, two amp modules with 900wrms between them and maybe some lit effects

Encountered some severe limitations in FreeCAD while trying to develop my base block using an arc in the sketch instead of curving the sides with fillets. This is for the clean lines that I showed in the previous post. Works and gets me a clean extrusion as shown. Well it's useless! Creating a structure using the arc tool is a dead end. The created surface cannot be further extruded in steps to create laminate layers. I am glad that I tried that. And I did try many variations over the past few hours. At least its good to know what rabbit hole not to jump down again. It is definitely not a problem though as starting from scratch, I can use fillets for shaping the side panel curves and push the edges of the fillets well into the sacrificial formers area at the ends. After forming the skins, I'll slice the ends away and replace with the solid baffle and rear panel, leaving no shape forming lines on any panel. So, no work limiting lines will appear on the model

Encountered some severe limitations in FreeCAD while trying to develop my base block using an arc in the sketch instead of curving the sides with fillets. This is for the clean lines that I showed in the previous post. Works and gets me a clean extrusion as shown. Well it's useless! Creating a structure using the arc tool is a dead end. The created surface cannot be further extruded in steps to create laminate layers. I am glad that I tried that. And I did try many variations over the past few hours. At least its good to know what rabbit hole not to jump down again. It is definitely not a problem though as starting from scratch, I can use fillets for shaping the side panel curves and push the edges of the fillets well into the sacrificial formers area at the ends. After forming the skins, I'll slice the ends away and replace with the solid baffle and rear panel, leaving no shape forming lines on any panel. So, no work limiting lines will appear on the model

post on the Freecad forum the limitations you encountered, maybe they will address those in the futureEncountered some severe limitations in FreeCAD while trying to develop my base block using an arc in the sketch instead of curving the sides with fillets.

so solidworks will we your tool of choice for 3D design, or Fusion 360, i heard that Blender can do pretty good 3D also but idk if the learning curve is step

- Home

- Loudspeakers

- Subwoofers

- Cub Sandwich